Ex-Situ Packed Bed Bioreactor (PBBR)

The reactor is made of fiberglass shells. Each reactor has 9 aeration cells with beads. The beads are designed in such a manner that the specific nitrifying bacterial consortium gets immobilized on the surface of the beads. The Packed Bed Bioreactor contains 60 kgs of beads with a surface area of about 28.26 m² and specific surface area of about 205 m² / m³ to facilitate removal of harmful nitrogenous compounds.A reservoir tank and a collecting tank are integrated for facilitating flow of water from the former to the latter.

The reactor is made of fiberglass shells. Each reactor has 9 aeration cells with beads. The beads are designed in such a manner that the specific nitrifying bacterial consortium gets immobilized on the surface of the beads. The Packed Bed Bioreactor contains 60 kgs of beads with a surface area of about 28.26 m² and specific surface area of about 205 m² / m³ to facilitate removal of harmful nitrogenous compounds.A reservoir tank and a collecting tank are integrated for facilitating flow of water from the former to the latter.

The Ex-Situ Packed Bed Bioreactor (PBBR) serves the purpose of reuse and recycling of spent water for larval production and for the treatment of fresh seawater taken into the hatcheries. This is a key component for the establishment of Recirculating Aquaculture Systems (RAS)

Applications

- Establishment of Recirculating Aquaculture Systems (RAS) for maturation and brood stock maintenance.

- Establishment of Recirculating Aquaculture Systems (RAS) for larval production.

- Nitrification of the incoming water.

- Spent water treatment and reuse.

Nitrifying bioreactors can be used for establishment of Recirculating Aquaculture Systems (RAS) in any marine water / brackish water / fresh water seed production systems including those of Prawn, Shrimp, finfishes, mollusks etc., and also in ornamental fish culture systems.

Biological Specifications

| Temperature | Tropical conditions-needs no heating and chilling cold condition-needs heating and chilling |

| Total surface area of media | 28.26 m² |

| Flow rate | 300-2500litres/hr |

| Peak TAN removal rate | 132g TAN/m³/day |

| Level of Dissolved Oxygen | 5.8 – 6.0 ppm |

| Nitrate Level | <8ppm |

| Backwash | Depends on load |

| Durability | Continuousrecirculationkeeps the system viable with sufficient aeration and ammonia loading |

Technical Specifications

| Water Salinity Range | 0,15, & 30 ppt (+/- 5 ppt) Three different cultures are available for the above mentioned salinity levels |

| Purification Capacity | 10000 -60000 lts / day |

| Water Input | 0.5 hp /230 volts Monoblock Pump |

| Water Drain system | 7 Individual gate valves |

| Air Supply | Air compressor (not with standard machine) |

| Power Supply | 230 V ac 1N-50/60 HZ 2.5A f.l.c(fully load current) |

| Machine Structure | MS fabricated body with Protective coating (As per International standards) |

| Process tanks | Food grade FRP |

| Aeration tubes & knob | Food grade tubes & Corrosion free pipes, Knobs |

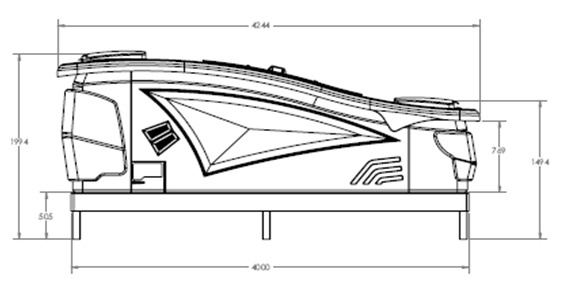

| Overall dimensions | 4.3Lx1.2Wx2H (Meters) |